DM Series Membrane Dryer

Reliable Compressed Air Drying without the need of Power or Service

Water and moisture in compressed air damages installations, machines and pneumatic controls. Corrosion and pockets of bacteria can form quickly. For that reason treatment of the compressed air is always required as a preventative measure, with minimum cost implications. BAMBI ® DM is the most compact BAMBI solution for drying compressed air to special demand requirements. Membrane dryers require no power and almost no service. Furthermore they only treat compressed air when it is needed, and at the required level of quality. The compact construction seems destined for mobile use but is also for stationary applications at the “point of use”. Whether in a dental laboratory, with an analyzer, or a printing machine in a factory building: BAMBI ® DM provides the best output, every time.

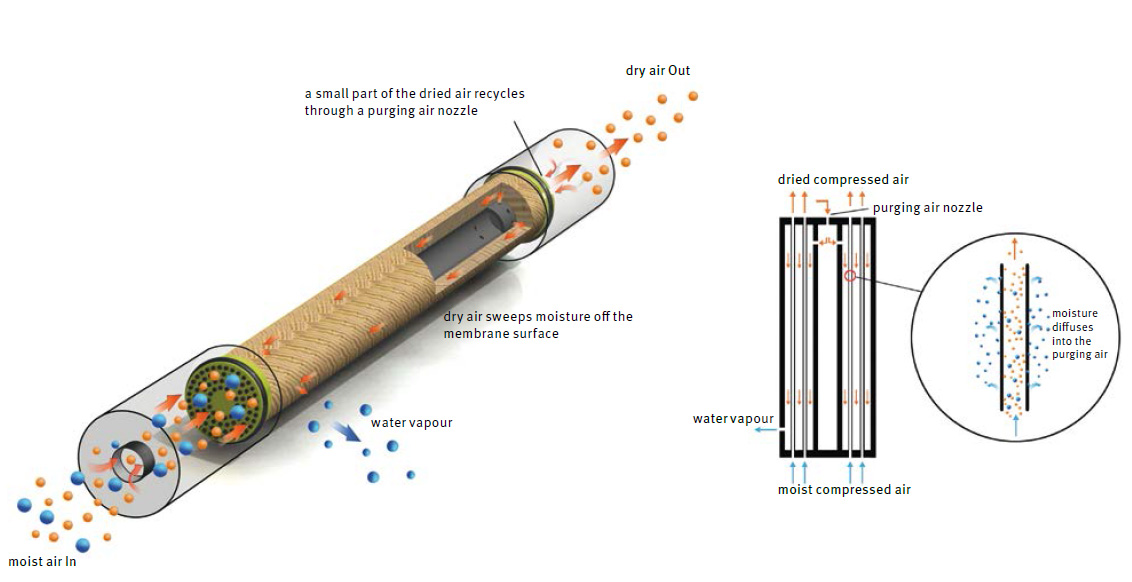

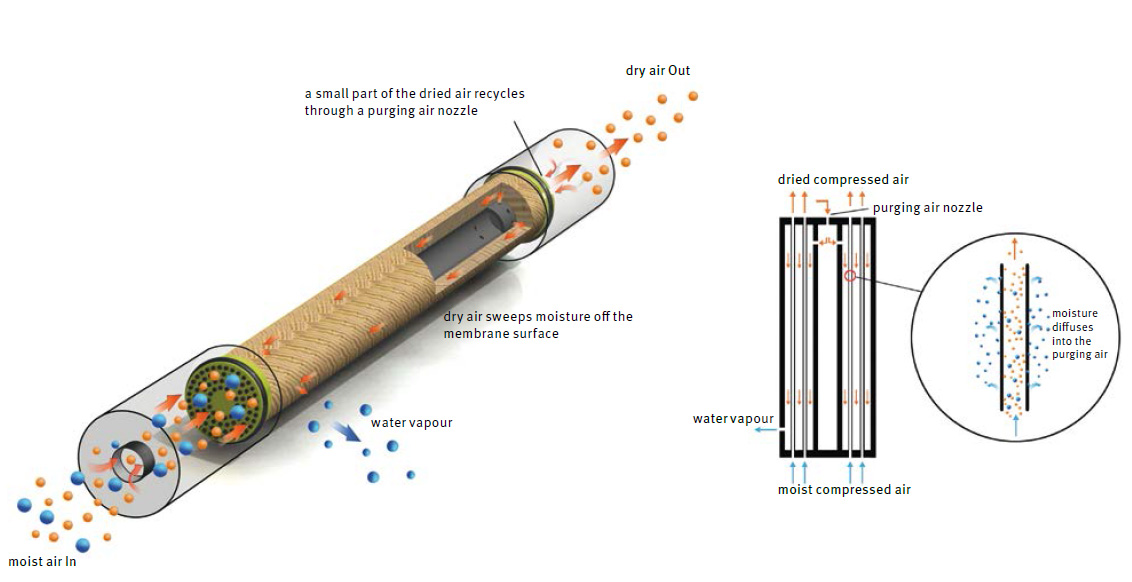

The diffusion process

The path of the compressed air through the membrane dryer

The compressed air flows into the dryer and is directed into the membrane element. The still moist compressed air then flows through the selective hollow fibre membranes interior. Purging air is continuously diverted back along the outer walls of the membrane element for the purposes of drying, and using a specific nozzle opening it is released to atmospheric pressure. Due to this expansion the purging air is now significantly dryer, due to the moisture being distributed across a larger expanded volume. In the process the dried purging air flows across the outside of the membrane.

Two air flows, separated only by the membrane wall and with different moisture content, move through the membrane element in a counter flow configuration. Due to the different moisture content the moisture in the compressed air diffuses into the purging air. The compressed air treated in this process is now dry when it leaves the membrane dryer.

BAMBI ® DM PLUS

Filtration at the 0.01 micron level prior to the membrane is strictly required In the BAMBI ® DM PLUS version BAMBI supplies a system solution of the membrane dryer combined with matching SMA prefilter and wall mount. The combination can be mounted in this case in a vertical or horizontal arrangement.

I would like to learn more about the parameters of membrane dryers. Please download the following information or call us at+86-21-51088285 or send an email to info@bambi-air.cn.

DOWNLOAD